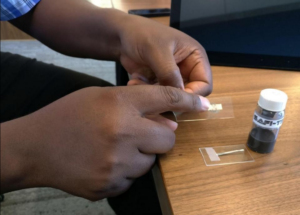

ISU professor Martin Thuo demonstrates soldered metal samples created by particles he developed. SAFI-Tech, a company started by one of his post-doctoral researchers, looks to bring the product to market. (Dan Mika/Ames Tribune)

A professor and two post-doctorate researchers at Iowa State University have secured a patent for a no-heat soldering technique almost as simple as using glue.

The solder material, which looks like black fluid at room temperature, is essentially bulk metal broken down into small liquid particles and encased in a chemical layer the size of a nanometer, roughly the size of a thousandth of a strand of human hair.

Ian Tevis, a former post-doctorate researcher at ISU and chief technical officer of SAFI-Tech, the company leading the solder product’s venture, said the process works like applying glue to paper: the user would apply the solder and apply pressure to let it set.

“Think of it like little water balloons filled with metal that cools when it’s popped,” he said.

Once set, the solder acts like a conventional solder, which can save manufacturers and tinkerers in time and money by not having to wait for an iron to reach the temperature required to melt the metal being used.

Ultimately, Tevis wants to develop a solder for general use, along with a replacement for electrically conductive silver paste for use in flexible electronics.

The technology was principally developed by Martin Thuo, an ISU professor, along with Tevis. Part of the product’s early development research was conducted at Harvard University, where Thuo spent time after getting his doctorate. But now, SAFI-Tech’s research and development efforts are housed entirely at ISU.

“Harvard is great for discovery and they have a lot of toys,” he said. “But we don’t need Harvard anymore for this.”

SAFI-Tech received $225,000 in seed money from the Small Business Innovation Research fund, an arm of the National Science Foundation, along with a $25,000 grant from the Iowa Innovation Corporation about eight months ago.

Tevis said he hopes to develop his solder to the point where it can be used for individual do-it-yourself projects and industrial-scale operations alike. The challenge right now for SAFI-Tech, Tevin said, is producing different types of solder for various applications.

“How do you pop one million balloons at once for a manufacturer?” he said.

SAFI-Tech must also battle challenges on the venture’s business side. The solders must achieve Restriction of Hazardous Substances, or RoHS, compliance before hitting the market. There are also several logistical issues in scaling the manufacturing process for different customers. The company is receiving support from Startup Factory, an ISU-sponsored business accelerator providing advice, resources and a workspace over a year.

For Thuo, the key issue is keeping the general population’s interest in the discovery until SAFI-Tech can bring a product to consumers.

“This started with one particle, which made us excited enough,” he said. “Does my grandma care? No … We can have the most important technology, but it’s useless if it can’t go to market.”

Tevis said projects funded by the SBIR fund aim for production within two to three years of winning a grant, so he hopes to have a product to market within that timeframe.

View at amestrib.com

Recent Comments